The main areas of application: installation of insulation and finishing panels of any size, block masonry, installation of decorative elements, gluing steps, plinth installation, window sills, etc. The product has excellent adhesion to most of building materials: polystyrene insulation boards (EPS, XPS), polyurethane boards (PIR), phenolic boards (PF), wood, concrete, bricks, ceramic and stone tiles, metal, gypsum, OSB, aluminium, etc. The foam has an extremely fast and strong initial grip, with a gluing time of just 2 minutes. Support is only needed for 1 minute, depending on the weight and size of the bonded element. The full cure time is 2 hours and cutting time is only 10 min., so FOME FLEX 120 SECONDS SPEED TACK ADHESIVE FOAM significantly speeds up and simplifies the work of finishing and construction works repairer. The foam yield at a 3 cm joint width is 80 meters, which allows up to 12 m2 of insulation or finishing elements to be installed and reduces transport costs comparing to dry mixes. This product meets the requirements of the M1 Emission Classification of Building Materials certificates, therefore it is environmentally friendly and absolutely harmless to human health.

- New

FOME FLEX 120 SECONDS Speed Tack Adhesive Foam

FOME FLEX 120 SECONDS SPEED TACK ADHESIVE FOAM is the fast primary grip adhesive foam, without secondary expansion, designed for bonding all insulating materials and most finishing, construction and renovation work.

- Bonds to the surface within 120 secs

- The output of the bottle is 12 m2 of insulation materials

- Bonds almost all insulation and finishing materials

- Yield 80 meters of seam (3 cm wide)

- Environmentally friendly and absolutely harmless to health

FOR BONDING POLYSTYRENE BOARDS TO ROOFS AND FUNDATIONS

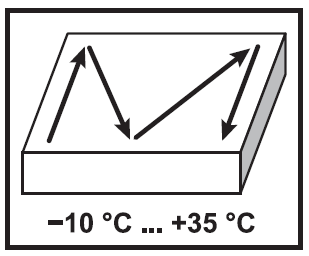

Shake the canister vigorously and screw the gun. Clean and moisten the working surface thoroughly. Screw the foam gun to the foam can. Turn the can upside down. To adjust the foam flow, regulate the valve on the back of the gun handle. Moisturizing accelerates polymerization. Apply a seam from a distance of 2-3 cm from the surface of Styrofoam board to create a letter “M”. After application, wait 2 minutes and apply the bonded material to the surface. Support is needed for up to 1 minute depending on the weight. For bonding large insulation panels, at least 10% of the surface must be covered. Correction time up to 8 minutes. After just 2 hours, the adhesive acquires the proper mechanical strength and the process can be continued. Working temperature from -10 °С to +35 °С. If the foam is used at low temperatures, the can must be heated to +18 °С by placing it in warm water or a warm room. Remains of non-dried foam are best cleaned with FOAM CLEANER FOME FLEX. Remove cured foam with HARDENED FOAM REMOVER FOME FLEX.

FOR BONDING POLYSTYRENE BOARDS TO ROOFS AND FUNDATIONS

Spray 3 parallel strips of 2-3 cm thick foam adhesive on the surface of the polystyrene board. The fastening of polystyrene foam panels depends on the specification of the ETIC system used and must be determined based on the ETICS technical documentation or the European Technical Approval Guidelines for ETICS.

| Indicator | Units | Certifications | Value |

|---|---|---|---|

| Colour | Grey | ||

| Yield | m2 | 12 | |

| Yield (3 cm joint) | m | 80 | |

| Cutting time | min. | 10 | |

| Curing time | min. | 120 | |

| Tack free time | min. | EOTA TR 46 | 5 |

| Temperature resistance after curing | °C | -40 … +90 | |

| Applications temperature | °C | -10 … +35 | |

| Tensile strength | N/mm2 | EOTA TR 46 | 0,14 |

| Thermal conductivity | W(m*K) | RB24 | 0,036 |

| Volume | ml | 750 |

Store upright in a dry place at +5 °C to +25 °C. Expiry date – 18 months from date of manufacture, subject to storage regulations. Protect canisters from direct sunlight and heat above 50 °C. Quantity per box – 12 pcs. Quantity per pallet – 672 pcs.