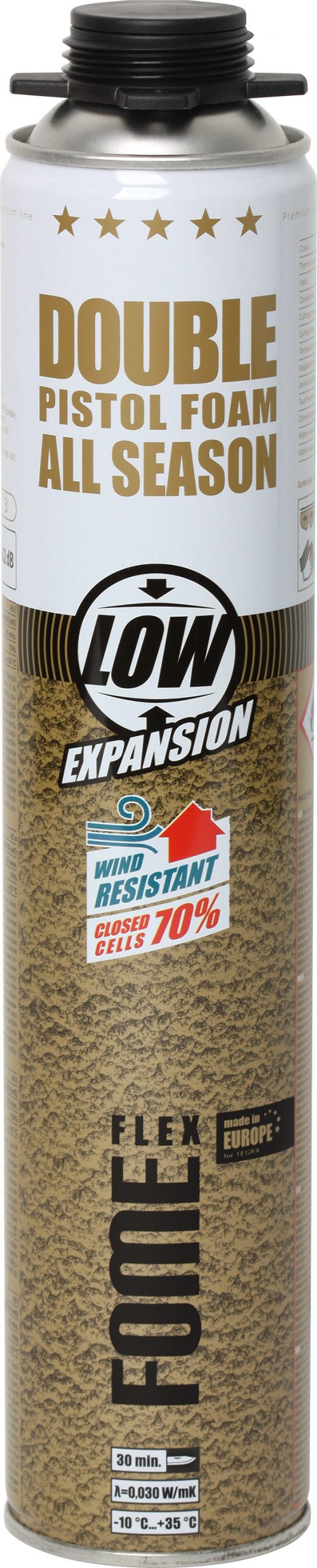

One-component polyurethane mounting foam FOME FLEX DOUBLE PISTOL FOAM. With the help of the new DOUBLE PISTOL technology, it is possible to work with both the pistol and the adapter that comes with the vial. The valve has an internal thread into which the adapter is securely screwed. It is possible to inflate some of the foam with the adapter, then unscrew it and continue working with the gun. The adapter helps you reach narrower and harder to reach places. When working with the gun, the foam has a low secondary expansion, only 30%. Yield of free-blowing 45 liters. You can cut in 20-40 minutes. Temperature resistance after hardening -40°C … + 90°C. Fully hardens in 80-100 minutes. Sound attenuation index 62 dB. The foam has 70% closed and 30% open pores, so it protects against wind, but breathes perfectly. Areas of application: window and door sealing; heat and sound insulation; acoustic insulation; filling cracks, cavities, gaps; pipe insulation; sealing of roof, wall and floor joints; thermal insulation of roofs.

FOME FLEX Mounting foam Double Pistol Foam

Professional mounting foam with double adapter, with the best thermal conductivity coefficient on the market and extremely low secondary expansion.

- Double adapter

- Extremely low thermal conductivity - 0.030 W/m * K

- Very low secondary expansion -30%

- Closed pores - 70%

Users manual – thoroughly clean and moisten the work surface. Shake the vial vigorously and screw on the gun. Invert the vial with the valve facing down. To adjust the mounting foam spray flow, rotate the valve on the back of the gun handle. Fill the cavity with foam. Application temperature from -10°C to +35°C. If the foam is used at low temperatures, the vial must be warmed to + 18 ° C after placing it in warm water or a warm room and do not moisten the surface. Do not wet the surface at air temperatures below 0 ° C. Residues of undried foam are best cleaned with Foam Cleaner Fome Flex. Remove hardened foam mechanically.

| INDEX | UNITS | VALUE | CERTIFICATION |

|---|---|---|---|

| COLOUR | YELLOW | ||

| YIELD | litre | 45 | FEICA TM1003 |

| CUTTING TIME | min. | 40 | FEICA TM1005 |

| SECONDARY EXPANSION | % | 30 | |

| FULL CURING TIME | min. | 80-100 | |

| COEFFICIENT OF THERMAL CONDUCTIVITY | W/(m*K) | 0,030 | |

| SURFACE TACK | min. | 8-12 | FEICA TM1014 |

| SOUND ATTENUATION INDEX | dB | 62 | |

| EXPANSION TIME | % | 70 | |

| SHRINKAGE | % | 5<MS<0 | TM 1004-2013 |

| TEMPERATURE RESISTANCE AFTER CURING | oC | -40°C…+90°C | |

| WORKING ENVIRONMENT TEMPERATURE | oC | -10°C…+35°C | |

| FLAMMABILITY CLASS | B3 | ||

| VOLUME | ml. | 750 |

Store upright in a dry place at a temperature of +5°C to +25°C. Shelf life – 18 months from the date of manufacture, in accordance with the storage rules. Protect the vials from direct sunlight and heat above 50°C. The amount in the box is 12 pcs. Quantity on the pallet – 840 pcs. Transport temperature from -5°C to +25°C.